7 Reasons for Epoxy Failure

An epoxy failure usually results in a messy and costly cleanup. Over the course of many years of experience installing epoxy coating over floor systems, and replacing failed coatings, we have identified 7 main reasons for epoxy failure, despite all the qualities of the material. We categorize these 7 reasons under 2 classes: human error and product shortcomings.

In this article, reasons 1 through 4 are related to human errors. Reasons 5 through 7 are related to the limits of epoxy as a coating product.

Epoxy is a wonderful compound, but its chemical properties are limiting. Technology progresses, and today, new types of coating products based on polys offer advantages over epoxy. We touch on these new compounds at the end of the article.

Without much ado, let’s dive into the 7 reasons for epoxy failure.

1. Poor Surface Preparation

Poor surface preparation accounts for 60-80% of premature epoxy failure. The preparation steps take time and a professional installer won’t cut corners. In the experience of MotorCity Floors and Coatings, surface preparation takes up 40-50% of the man-hours invested in any project.

Professional installers prepare concrete surfaces using refinishing machines (floor grinders, polishers). Then they properly clean, degrease, and sand the surface before applying the epoxy. If the installer does not take the time necessary to perform each of these steps in sequence, the epoxy coating will not adhere properly and will start to peel and flake off sooner than normal.

Epoxy Must Bond to Concrete

Epoxy actually bonds to concrete at the molecular level because of two different mechanisms: chemical bonding and mechanical interlock.

Mechanical interlocking occurs when materials fill microscopic valleys, creating anchors that resist environmental and operational stresses. You can think of it like Velcro—the epoxy flows into the tiny peaks and valleys of the concrete surface, and when it cures, these microscopic “hooks” lock the coating in place.

At the chemical level, epoxy forms molecular bonds with the concrete surface. For epoxy to bond properly, it must “wet” the concrete surface—i.e. it must spread out and make intimate molecular contact.

3 Key Prep Steps

These 3 steps take care of the mechanical and chemical interlocking:

- Mechanical abrading (grinding/shot blasting) creates the surface profile needed for mechanical interlocking and exposes fresh concrete for chemical bonding.

- Cleaning removes contaminants that block chemical bonding and prevent wetting.

- Removing laitance (the weak, powdery surface layer on new concrete) ensures epoxy bonds to sound, structural concrete.

Unfortunately, there are contractors on the market who do not possess the knowledge and know-how to install this product correctly. They cut corners in their preparation process, and this always results in an epoxy failure.

2. Incorrect Mixing Ratio

Another common reason for epoxy failure is an incorrect mixing ratio. Most epoxy coatings require a specific ratio of resin to hardener in order to cure properly. Unlike poly resins (polyurea, polyaspartic), the installer can’t vary the mixing ratio of epoxy resins.

They must observe proper mixing ratios as accurately as possible to obtain optimum properties. If there is no precise measurement of the ratio, the epoxy will not cure correctly and will eventually crack and fail.

Floor coating professionals know this rule, and this cause of epoxy failure most often occurs in cases where an amateur did the coating.

Buying a home? Request invoices

When you buy a home with an epoxy coating in the garage or basement, ask your Realtor® to request from the current owner the invoices showing a professional took care of the coating. Don’t just assume this is the case.

If the seller can’t produce an invoice, request the name of the installer. Verify directly with them that they did the job. If you can’t verify it, you risk facing an epoxy failure much sooner than you would wish. The next professional installer will have to remove the failed coating and re-do the job. This removal job will cost you extra, and at that point you may be out thousands of dollars.

Common mixing ratios:

- 1:1 ratio (by volume) – requires precisely equal amounts of resin and hardener

- 2:1 ratio – 2 parts resin to 1 part hardener

- 5:1 ratio – five parts resin with one part hardener (for certain systems)

3. Improper Curing

The mixing ratio determines curing. When the mixture is incorrect, the epoxy won’t cure properly and won’t reach its full strength. It will start degrading earlier than normal and at a much faster rate.

Most epoxies require 72 hours to cure completely, The coating becomes hard to the touch after approximately 24 hours but it continues to cure for a full two weeks to reach its full strength and durability.

Avoid Early Stress

Moreover, you can’t subject a freshly laid epoxy coating to immediate stress: while you can technically walk on epoxy 3 days after it was applied, best practice is to wait until it is fully cured before putting any heavy stress on it. As an example, BEHR recommends allowing 24 hours for light foot traffic, 72 hours for heavy foot traffic and furniture, and 7 days before subjecting to automotive tires.

Although the epoxy will be dry to the touch in about 8-10 hours, the chemical curing process is still going on. Technically speaking, the molecular cross-linking is still occurring and as time goes on the cross links get tighter — which means the coating is getting stronger and harder. The full cure stage can take 7-10 days. At that point, the epoxy will reach its maximum hardness and chemical resistance.

As you can see, waiting reduces the risk of epoxy failure.

4. Incorrect Application

Since epoxy is a two-part adhesive that the installer mixes and then applies, the epoxy will start to harden and cure within minutes. Time is of the essence here, and installers work quickly when applying it. They should apply the epoxy in thin layers, making sure there are no air bubbles in the adhesive. If they don’t apply the epoxy correctly, it won’t adhere properly to the concrete surface. Within a short time, the topcoat will start peeling and flaking off.

Also note that epoxy resin has an exothermic reaction at 55°F. When the temperature is lower, epoxy floors take longer to cure. They won’t bond and adhere as effectively. This results in an epoxy failure due to reduced strength and durability.

Professional installers may use pre-warming methods (blanket-warming the concrete, using heat guns on the concrete, warming the epoxy itself to 77°F before pouring) to lay down epoxy layers. But many just prefer to wait until the weather warms up to schedule a job.

5. Poor Quality Epoxy

Another reason for epoxy failure is due to a product of poor quality.

Quality epoxies contain specific formulations that affect performance. High-quality, UV-resistant epoxy systems are formulated with special raw materials that withstand UV damage and prevent yellowing and discoloration, the two hallmarks of a UV-induced epoxy failure.

Commercial products include TINUVIN Carboprotect for aromatic epoxy systems, which allows less than 1% UV transmittance up to 420nm, and TINUVIN 928, a hydroxyphenyl benzotriazole class UV absorber developed specifically for high performance coating applications. The manufacturer-recommended concentration of Tinuvin 1130 UV stabilizer for epoxy resin is 3% by weight.

Lab Testing

Laboratory testing has clearly established the vulnerability of epoxy to UV exposure.

- After 800 hours of UV radiation, epoxy samples without UV absorbers showed severe yellowing, while samples containing 3% Tinuvin 1130 showed only low-intensity yellowing, demonstrating effective protection.

- Unprotected epoxy degrades in 6-12 months under constant sun exposure, while stabilizers can extend this to 5-10 years depending on formulation and environment, with a 2024 study on marine coatings finding stabilized epoxies lasted 3 times longer than unstabilized ones.

- Advanced formulations using anthracene-based modifiers showed only 2.6% tensile strength loss and 10.8% fracture toughness loss after 400 hours of 340nm UV exposure, compared to 33.1% and 61.5% loss in control (unprotected) samples.

From these lab tests, we can see that exposure to UV not only affect the color of the epoxy (yellowing) but also its strength (flaking).

In other words, the quality of the epoxy material selected by your flooring contractor will definitely affect the durability and aspect of your epoxy coating years down the road.

When you discuss with your installer, you need to ask questions about the UV resistance of the epoxy to be used on your floor. Do not skimp on the material. Pay more to secure the future of your coating and avoid an early epoxy failure.

6. Poor Storage Conditions

A common reason for epoxy failure is due to poor storage conditions. Epoxy is a sensitive material. Extreme temperatures, humidity, and sunlight will degrade it, especially if it hasn’t been cured properly.

Proper Storage Guidelines:

- Two-component epoxy resin systems last longer in storage comprised between 72°F – 74°F in a dry, low humidity environment.

- Unmixed epoxy components fare best within a temperature range of 60°F to 80°F.

- Exposure to low temperatures during storage (<55°F, <12°C) may cause the resin to crystallize.

Shelf Life:

- Unopened containers have a shelf life of one year when stored properly

- Open bottles have a shelf life of about two months due to oxidation from oxygen exposure.

- With proper storage, resin and hardeners should remain usable for many years, though manufacturers typically recommend testing material that is more than a year old.

If you store the epoxy in an environment that is too hot or too cold, it can degrade and eventually fail.

In practical terms, how can you be sure that the material you purchase through your flooring contractor has been properly stored? For one thing, you can check the date of manufacturing printed on the cans when your contractor brings the epoxy material to your home on the day of.

7. Other Degrading Risk Factors

As we have seen earlier, environmental factors can directly degrade the epoxy material and its application on a floor. We discussed UV resistance, temperature sensitivity, as well as the preparation steps your floor coating installer takes to ensure good bonding to the concrete surface.

But there are other factors at play that can lead to an early epoxy failure.

Moisture

Moisture can break down epoxy. How?

Scientists attribute the material degradation mechanism to hydrolysis: the epoxy resin ester bonds into organic acids and alcohols under heat and humidity stresses. Water molecules cause plasticization of the resin matrix and damage the interfaces between resin and reinforcing fibers. In other words, epoxy breaks down in the presence of water content.

Acid Spills

If you spill acid on your epoxy-coated floor, it will suffer damage. Acid lowers the pH of epoxy and “digest” it, breaking it and degrading it in the process. The dominant degradation mechanism in concentrated hydrochloric acid is physical in nature, with formation of surface cracks driven by swelling stresses due to core-shell swelling behavior, leading to an erosion-type degradation phenomenon.

Solvent Spills

All polymeric coatings are somewhat permeable to chemicals. Chemical attack of thermoset coatings involves three processes: swelling of the polymer network, chemical diffusion into the network, and chemical reaction and degradation. Don’t drop solvent on your epoxy coating.

Reducing the Risk

Considering these risks, the decision to coat your floor with epoxy should depend to a large degree on the use you have of the space. If you coat your basement because it’s where your kids play or where you have your man-cave, epoxy is probably a good choice because of its hardness and capability of sustaining foot traffic, and because the space won’t likely be subject to hard chemical attacks. If you spill coffee, water, or a glass of whisky, just mop it quickly. Voilà! No foul.

However, if you want to coat your garage where you also have a workbench and a cupboard full of solvent and acid bottles, you are now facing multiple risks. You can car leak oil, gas, battery acid. Your tires will bring chemicals from outside (salt, acidic grime, etc.). You can drop a bottle of solvent and spill it on your beautiful epoxy… Your tires will be hot after driving, and their temperature may exceed the epoxy temperature tolerance: your tires would leave black marks on the floor, and these can’t be cleaned up.

All in all, epoxy is not necessarily the best coating for a garage. Too many risks factors that will lead to epoxy failure.

The Alternative to Epoxy

MotorCity Floors and Coatings has been in the floor coating business for years. We have installed our fair share of epoxy flooring. We love the product but we also are very aware of its shortcomings.

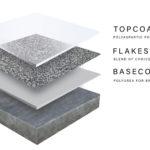

Today, we recommend our clients to opt for a blend of polyurea and polyaspartic coatings. We have perfected this type of dual coating to a high level of durability. Using a polyurea coat as the basecoat over the concrete surface, and the polyaspartic product for the topcoat, we are able to install in our clients’ homes a coated flooring that flexes with the concrete (and avoids cracking), is extremely durable (we are talking decades), is very easy to maintain (simple mop with water), and will keep its beautiful appearance for years.

Call us at (248) 613-5888 to discuss your options. Our floor coating specialists have years of experience under their belt, and they are able to ask you the questions that matter to make the correct decision and avoid an epoxy failure 3-5 years down the road.

MotorCity Floors and Coatings is a concrete floor coating specialist operating in Novi, MI and servicing clients throughout the Metro Detroit area. Our clients love our work, and they have given us a 4.9 rating in Google Reviews.