Polyurea Concrete Coatings: What Roles Can They Play in Our Lives?

Polyurea concrete coatings are gradually replacing traditional coating materials such as latex and epoxy. This trend promises to continue for years to come because of the chemical and physical properties of this type of polymers, their durability, and their resistance to common stressors.

For all their ubiquity in our world in the past 80 years, concrete surfaces have rarely been protected against pollution, seasonal temperature swings, and typical anthropogenic degradation by more than just a few coats of latex paint. Whether used in infrastructural projects or government and private buildings, concrete has been widely perceived as capable of outlasting its economic use with minimal degradation outside of unpredictable acts of God. Latex paint was a convenient material to refinish surfaces in urban environment.

Yet, it has become abundantly clear since the late 70s that, attacked by a combination of aggressive factors, reinforced concrete would degrade to a point of losing its architectural appeal and structural integrity. Advances in chemical science have yielded new high-performance coating materials capable of slowing down its inevitable degradation.

Among those, polyurea stands out as a remarkable option, known for its exceptional capacity to adhere to concrete and resist the aggression of external stressors. In this article, we will explore the science behind the bond strength of polyurea concrete coatings and why it is crucial for the longevity and performance of concrete structures.

The Science of Polyurea Bonding

The bond strength of polyurea concrete coatings is a result of a fascinating chemical process which consists in making an isocyanate component react with an amine-terminated resin. The blend results in the formation of strong urethane linkages. This rapid reaction allows polyurea to develop robust chemical bonds with the concrete substrate, creating a quasi-inseparable connection.

Unlike some other types of coatings, polyurea does not merely adhere to the surface of the concrete; it forms a cohesive bond that penetrates into the micro-pores and capillaries of the concrete matrix. This intimate connection results in an extremely strong and durable bond that resists delamination and provides exceptional protection against various environmental and mechanical stresses

Research in the Journal of Materials in Civil Engineering investigated the impact resistance of polyurea-coated high-performance cementitious composites. The study found that a polyurea coating significantly increased the flexural strength and toughness of the composite material. Drop-weight tests demonstrated a visible reduction in damage on coated specimens, with the coating on the tension side being particularly effective. This research underscores polyurea’s ability to mitigate damage from direct impacts.

Polyurea Concrete Coatings: Adhesion to Substrates

Polyurea can form powerful bonds with a wide range of concrete substrates. Whether it’s new or old concrete, smooth or textured surfaces, the bond strength of the material remains the same. This versatility makes it well-suited for various applications: industrial floors, parking garages, warehouses, and decorative surfaces.

Durability and Impact Resistance

One of the key reasons why polyurea stands out as a concrete coating is its durability and impact resistance. Once bonded to concrete, polyurea forms a tough, flexible, and seamless protective layer. It can withstand heavy foot traffic, mechanical loads, and even the impact of falling objects without showing signs of chipping or cracking. This exceptional resilience translates into long-lasting protection for the underlying concrete, extending its service life.

A study published by researchers from the Universitat Politècnica de Catalunya investigated the durability and impact performance of polyurea-coated prestressed concrete beams. The results indicated that the polyurea coating not only protected the beams from corrosion but also significantly enhanced their load capacity and ductility. In impact tests, the coated beams absorbed forces more effectively, leading to reduced structural damage.

A key characteristic of polyurea highlighted in scientific literature is its significant strain-rate sensitivity. This means that the material’s mechanical properties, such as its stiffness and strength, increase as the speed of the impact or loading increases. A review on polyurea for blast and impact protection, available through the National Center for Biotechnology Information (NCBI), details this phenomenon. This property is particularly valuable in applications where sudden impacts are a concern, as the polyurea effectively becomes stronger when it needs to.

Chemical Resistance

Polyurea shines in industrial environments or areas prone to exposure to chemicals. Its high chemical resistance makes it impervious to the corrosive effects of acids, oils, solvents, and alkalis. Chemical resistance shields the concrete substrate from chemical attack, preventing premature degradation and maintaining structural integrity.

A study published in the Journal of Materials in Civil Engineering investigated the performance of polyurea coatings on concrete exposed to sulfuric acid. The results indicated that the polyurea provided a highly effective barrier, significantly slowing down the degradation of the concrete. Similarly, studies have demonstrated its resistance to common alkalis. The dense, cross-linked molecular structure of polyurea creates a low-permeability barrier that prevents corrosive agents from reaching the underlying substrate.

Polyurea generally performs well when exposed to various solvents and hydrocarbons, which is why it often finds a use as secondary containment applications in the oil and gas industry. Research in publications like the Journal of Protective Coatings & Linings has detailed the testing of polyurea against substances like diesel fuel, gasoline, and various industrial solvents. While prolonged immersion in highly aggressive solvents can cause some swelling or degradation, specially formulated polyureas (aromatic and aliphatic) show robust resistance for spill and splash protection.

Some academic research compares the chemical resistance of polyurea with other coatings like epoxy. For instance, a study in the journal Progress in Organic Coatings might compare how different coating systems, including polyurea and epoxy, withstand immersion in various chemical solutions over extended periods. These studies often find that while epoxy coatings can offer excellent resistance to a specific set of chemicals, polyurea systems often provide a broader range of protection, particularly when the application requires flexibility and crack-bridging capabilities.

Key Takeaways for the Concrete Floor of Your Garage

The bond strength and other properties of polyurea concrete coatings make them well-suited for a garage floor:

- Long durability, up to 15 years: with proper maintenance, you will secure your investment for the next 15 years

- Good flexibility: adapts to motions in the concrete base of your garage

- Strong resistance against chemical spills: your floor coating will remain unperturbed by oil, gas, even acid spills

- Strong resistance to impact: if you drop your tools, the coating will be less damaged than on a floor coated with epoxy or a latex paint

- Strong resistance to temperature differences: no black tire marks when you park your car

- Easy clean-up with a vaccum-cleaner and a mop

- Fast curing time for a much quicker installation: MotorCity offer one-day installations for garage floor coatings

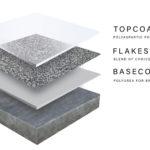

MotorCity is a well-known floor coating specialist based in Novi, MI. We serve families and businesses in the entire Detroit Metro area. Our customers love the work we do: over the years, we have gathered a 4.9 Google rating over 420+ reviews. We typically recommend a combination of polyurea and polyaspartic coatings to obtain a great look and a long-duration protection for your concrete garage floor.