All garage floor coating professionals agree on this technical truth. The concrete prepping work done before laying down the floor coating material determines the success and longevity of the coating work. It is as crucial as the type of epoxy used for the job.

In fact, most cases of coating failure are attributable to shoddy concrete prepping work.

This is what Jake Lowry, CFO of MotorCity Floors and Coatings in Novi, MI says about it:

“When it comes to concrete prepping work, let’s say we get to a floor first thing in the morning. We’re there between 8:00 AM and 9:00 AM. The first thing we do is identify: (a) If there’s a current coating on the floor. All this will be in the notes from when our salesperson comes out and does our quote. Our technicians will know exactly what’s to look forward to in the preps. (b) Whether or not there’s pitting going on from salt, which is pretty common here in Michigan. And (c) if there are cracks throughout the floor that need to be fixed.

The very first thing they do when they go in: they’ll diamond-grind the entire floor. They’ll use a 5-inch or a 7-inch grinder along all of the seams and the sides of the garage. We want to make sure we’re grinding the entire surface. We seek to get a nice opening-up of the pores of the concrete. That way, our coating can then bond to it properly.

After we do our initial pass, we make our repairs, with our product MR 50 or a polygrout.

After we do that, we let it sit for about 45 minutes or so. Then we grind those areas that we just prepped. And only then we are ready to apply the coating to the floor.”

Summary: Concrete prepping work for an epoxy floor coating job

- Evaluate the condition of the concrete (existing coating, pits, cracks)

- Diamond-grind the floor, including all seams and all sides

- Repair the pits and cracks with MR50 or polygrout

- Let the repair material sit for 45-60 min and apply the base coat

Garage floor coating professionals use best practices to prep up the concrete. The goal is to ensure the support on which the base coat rests offers maximum adherence. Likewise, we fill up dips and crevices with the correct products. This helps the coating paint to be laid down evenly over the concrete. In this way, we obtain a beautiful, shiny and flat surface. Without concrete prepping work, your floor coating will peel off, break down, discolor, and look shoddy.

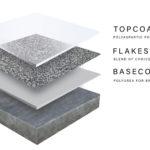

MotorCity Floors and Coatings has a long experience of indoor and outdoor floor coating work. We use a mix of polyurea and polyaspartic coating paints for maximum longevity and minimum clean-up effort. Our team serves residential, commercial, and industrial clients. We offer them a large palette of colors. From neutral tones to denser hues, we create a brand-new floor: easy to look at, easy to work on, easy to live with.

Call our garage floor coating professionals at (248) 613-5888. They will offer practical advice in picking a floor coating color and type best suited to your application.

MotorCity Floors and Coatings has its headquarters in Novi, MI. We are floor coating specialists, serving families and businesses in the entire Detroit metro area.