For years, epoxy has been the favorite type of floor coating of homeowners wanting a nice-looking, shiny, clean-looking garage floor, or patio, or even walkways. But with the years, epoxy has started to show its limits as a material. To then point that other forms of garage floor coating like polyurea and polyaspartic materials have started to gain traction, both in the residential, the commercial, and the industrial markets.

To discuss the downsides of using epoxy for floor coating, Jake Lowry comes to the microphone. Jake is the CFO of MotorCity Floors and Coatings. This is what he says:

Pitfalls of Epoxy

“Among the downsides that can come with using a standard epoxy, it’s not flexible, not nearly as flexible as if you were going to do a polyurea and polyaspartic floor.

Concrete does two things: it turns gray and it cracks. And when it cracks and wants to move, you want your coating to be able to bend and move with it to help relieve any of those stress joints; so that way, your coating doesn’t crack as well.

But epoxy is so hard that any shift like that will crack right through the epoxy as well. We see it all the time. It’s one of the reasons why we come out and remove existing coatings, so we can put down our own coatings. Epoxy is failing because it’s cracking.

The Dreaded Tire Marks

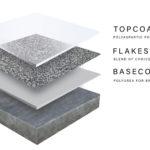

Another issue with it is hot tire pickup. This comes from a chemical reaction: you’re driving around all day, your tires get hot from driving around on the asphalt. You pull into your garage and all of a sudden now, on your epoxy floor, because it’s not resistant to it, you have black marks from your tires. They get too hot and they don’t bond well with the epoxy floor coating. That’s one of the things that our coatings using polyaspartic material for the top coat is heat resistant.

Other downsides with using epoxy for floor coating: it’s not salt resistant. In Michigan, we’re always dealing with winters where we have to use salt to help break up any ice that can eat away epoxy coating.

Epoxies are also not UV stable: you can have some issues with discoloration or yellowing. That’s one of the benefits that come with the polys top coats: they are 100% UV stable, so our coatings will never discolor or fade over time.

Installation Speed Matters

Also epoxy coating takes longer to install because you have to wait in between coats for it to cure. The wait time in between can be about 12 to 24 hours, depending on the thickness of each layer. Whereas with our system (polyurea coating + polyaspartic coating), we can wait one hour before we put on our top coat.

The last issue that I want to touch on, is that traditional epoxies can’t be installed in temperatures lower than 55°F. One of the benefits of our polyurea + polyaspartic system is that we can install in temperatures as low as -35°F. Now, if it ever gets to -35°F, you probably won’t see us out there installing… but it is definitely a benefit for us to be able to go ahead and install during the wintertime our coatings, rather than trying to do an epoxy.

Summary: Downsides of using epoxy for floor coating

- Epoxy lacks flexiblity: epoxy cracks when the concrete moves

- Hot tires leave dark marks on epoxy

- Epoxy is not UV stable: it becomes yellowish with time

- Epoxy is not salt resistant; in cold regions, salt eats it away

- Epoxy takes longer to install than polyurea coating

- Epoxy can’t be installed at temperatures lower than 55°F

Epoxy is a beautiful material for floor coating. But its chemical properties limit its use to certain applications in certain climates. New materials like polyurea and polyaspartic coatings are now replacing epoxy as the floor coating material of choice of contractors.

MotorCity Floors and Coatings has a long experience of indoor and outdoor floor coating work. In many cases, we install a combination of polyurea and polyaspartic coating for longevity and light clean-up. Our team of floor coating specialists serve residential, commercial, and industrial clients. We offer a large palette of colors, from neutral tones to denser hues. With your help, we will create in your home a brand-new floor, easy to look at, easy to maintain, and easy to live with.

If you plan on using epoxy for floor coating, let us invite you to call our professionals. They will offer practical advice in picking a floor coating color and type best suited to your application.