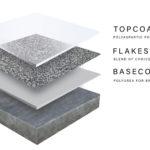

Polished concrete floors are among popular flooring options in industrial applications today. Concrete polishing is a process by which a flooring contractor transforms a dull, stained, cracked concrete floor into a high-gloss, durable, and long-lasting surface. The process involves grinding the surface of the concrete with progressively finer diamond abrasives until the desired level of shine is achieved.

Drawbacks of Un-polished Concrete

As a building material, concrete has no peers in terms of being able to withstand heavy foot and car traffic, heavy machinery, and other industrial equipment. But it also has some clear drawbacks, including:

- Cracking and Spalling: Concrete is prone to cracking due to temperature fluctuations, shrinkage during curing, and heavy loads. These cracks can evolve into spalling, where the surface of the concrete chips and breaks away, creating an uneven and hazardous surface.

- Dusting: A fine powder can form on the surface of a concrete floor, a phenomenon called dusting. This often results from improper curing or a poor concrete mix. Dusting not only creates a cleaning challenge but can also contaminate products and equipment.

- Moisture Issues: Concrete is porous and can absorb moisture, leading to a host of problems. Efflorescence, a white powdery deposit, can appear on the surface. More critically, trapped moisture can lead to the growth of mold and mildew, posing health risks and potentially damaging stored goods. Moisture can also cause coatings and sealants to peel and fail.

- Chemical Damage: Concrete is susceptible to damage from chemical spills. Acids and other corrosive substances will etch and degrade the surface, leading to structural weaknesses and subsequent safety hazards.

Polished Concrete: Reducing the Drawbacks of Concrete

One of the main benefits of a polished concrete floor is an increased durability.

- Densification: The process reduces the porosity of the material through the application of a chemical densifier that penetrates under the surface and creates a chemical bond hardening and densifying the surface.

- Stain resistance: A less porous surface is more resistant to the absorption of liquids (water, oils, chemicals). By facilitating the formation of a barrier at the top of the surface of the polished concrete, the process minimizes staining and the potential for moisture-related issues like efflorescence (salts coming up to the surface from under the concrete).

Polished Concrete: Lowering Costs

Polished concrete floors are also low-maintenance, an essential quality in industrial settings. Unlike carpet, tile, and other flooring options, polished concrete floors don’t require regular cleaning or replacement. With proper sealing and maintenance, this type of floor should last for decades, a very cost-effective option.

Additionally, there is no need to wax a polished concrete floor, or to reapply any coating periodically to remove chipping, peeling or wear. This contributes to lowering the cost of maintenance.

In regard to cracking: concrete will crack, polished or not, due to settling and temperature changes. However, new cracks can be repaired and incorporated in the polished surface.

Also of note, polishing applies to an existing floor and the process is fast. So it is cost-effective for businesses looking to update their flooring without a complete remodel, always disruptive.

Improving the Appearance of a Facility

A well-polished concrete floor has a sleek, modern look that enhances the aesthetic appeal of any industrial facility. The level of shine obtained during the polishing process can be adjusted to create a matte or glossy finish. A high-gloss finish reflects ambient light, making any workshop or warehouse brighter and more inviting. It is also possible to finish the polished concrete floor in a variety of colors and patterns: this customization enhances the brand identity of the business.

Environmentally Friendly, Safer for Health

Polished concrete is also environmentally friendly. In itself, the process of polishing is energy-efficient and generates minimal waste. Concrete is made from natural materials and does not need synthetic flooring materials harmful to the environment. Polished concrete floors don’t emit toxic fumes, and the process eliminates dusting which makes the material safer by preventing the risk of dust inhalation.

Concrete is naturally slip-resistant, but polished concrete is even more slip-resistant, reducing the risk of slip-and-fall for employees and suppliers.

Concrete floors are also hygienic. Unlike other flooring options such as carpet or tile, polished concrete floors do not harbor dirt, dust, or allergens. Furthermore, the smooth surface of a polished concrete floor prevents microbial growth. Dirt and debris do not get trapped as easily, and spills can be wiped up without leaving traces of harmful chemicals in the pores of the material.

Thinking of Having a Polished Concrete Floor? Call MotorCity Floors and Coatings!

MotorCity is a well-known flooring specialist based in Novi, MI. We serve businesses and families in the entire Detroit Metro area. Our customers love the work we do: over the years, we have gathered a 4.9 Google rating over 420+ reviews. Polished concrete floors is an option that our business clients often adopt for their warehouses, shops, factories, and showrooms. Our process is time-proven, and we strive to minimize disruption of your ongoing operations. To discuss your project and get a quote, please call us at (248) 613-5888 or click here to use our Contact Form for Industrial & Commercial applications. We will respond quickly to any request.