P

Polyaspartic coating is becoming increasingly popular for garage and basement floors, and for good reason. They offer many benefits over traditional epoxy coatings, which make them a great choice for homeowners looking to upgrade these floors to livable spaces.

Polyaspartic Coating: What Is It?

Polyaspartic coating material is a type of polyurea, which is a class of synthetic polymer that features both urethane and epoxy properties, and is characterized by its exceptional strength and durability. The material is often used in high-wear applications, such as floor coatings, where they can withstand heavy traffic and abuse. This unique combination of properties makes polyaspartic material well-suited for garage floor coating applications.

Polyaspartic coating is highly resistant to abrasion, chemicals, and weathering. It is also very flexible, which helps it resist cracking and chipping. Polyaspartic coating can also be applied to a variety of surfaces, including concrete, metal, and wood, and it can be used both indoors and outdoors.

Polyaspartic coating has been widely adopted for commercial and industrial applications, but its use is becoming increasingly popular in residential settings. Its durability and versatility make it a great product for a variety of applications, such as garages, driveways, patios, and decks.

What to Expect During Installation

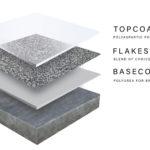

A polyaspartic coating is typically applied in two or three coats. The first coat is a primer that helps the coating adhere to the surface. The second coat is the actual polyaspartic coating, which is applied in a thick layer. The third coat, if used, is a topcoat that provides additional protection and durability.

Here’s what you can expect during installation:

Polyaspartic coating is typically applied 2 to 3 times on a concrete surface.

Step 1: We prepare the surface. Using diamond-tipped grinders and high-powered industrial vacuum cleaners, we make sure that the surface is clean and debris-free.

Step 2: We ensure a moisture-free surface. We fix and fill any holes, gaps, or cracks with a quick-cure compound before grinding them. This is to ensure that the floor is evenly levelled and won’t cause moisture build-up in the future.

Step 3: Next, we apply the base coat to the concrete surface using brushes and rollers. Why brushes and rollers? To reduce the dispersal of polyaspartic material into the air.

Step 4: We apply the second base coat. While the second coat is curing, we manually spread flakes or chips of vinyl over your garage floor. Then, we scrape and vacuum the loose flakes after curing, right before we apply the clear top coat.

A polyaspartic-coated garage floor will be ready for foot traffic after two hours of curing and for vehicle traffic 24 hours after application. The curing process of the material is much faster than traditional epoxies, which take about 72 hours of curing before the garage floor can see any kind of foot and vehicle traffic .

A Polyaspartic Coating is Different From Epoxy

There are a few key ways in which a polyaspartic garage floor coating differs from typical epoxy coatings:

Durability: Polyaspartic coating is significantly more durable than an epoxy coating. It is resistant to chipping, cracking, and peeling, and it can withstand heavy traffic and heavy weights.

Chemical Resistance: Polyaspartic coating is highly resistant to chemicals such as oils, gasoline, and to cleaning products. This makes them an great choice for garage floors, often exposed to these types of chemicals.

UV Resistance: Polyaspartic coating is also more resistant to UV light than epoxy coatings. It will not yellow or fade over time and will stay looking new longer.

Flexibility: Polyaspartic coating is more flexible than an epoxy coating, which means it is less likely to crack or chip.

Thickness: Polyaspartic coating can be applied in a much thinner layer than an epoxy coating. The coating process will not add as much height to your floor. The material also cures much faster than epoxy, so you can get back to using your floor in no time.

Overall, a polyaspartic garage floor coating is a great option for anyone looking for a fast-curing, durable, and easy-to-use coating. If you’re considering a new garage floor coating, definitely include the polyaspartic route in your options!

Conclusion

If you’re considering a new coating for your garage floor, you may be wondering whether to choose epoxy vs polyaspartic. At MotorCity Floors and Coatings, we specialize in both types of coatings and can recommend the best type of coating for your needs. Our coating process is superb and can transform any concrete floor into a stronger, more attractive concrete space. Let us help you find the perfect solution for your garage floor. Contact us at (248) 613-5888 to get professional advice and a quote.