Do you know that polyaspartic patio coating is a thing in the Detroit Metro area? We do! When the weather gets warmer, people spend more time outside on their patios. They want to extract maximum pleasure from their time outside. How can you to enjoy your patio to the max? Freshen it up with new coating!

In this area, people have choices: paint, epoxy… and polyaspartic. We love polyaspartic coatings: they are durable, beautiful to look at, they stretch when temperatures go up to avoid breaking, they are UV resistant… A smart choice!

Polyaspartic Patio Coating: What is it?

Polyaspartic coatings are a type of protective coating based on aliphatic polyurea technology. They are essentially a specialized form of polyurea that uses polyaspartic ester chemistry, which consists of the reaction between a polyaspartic ester and an aliphatic polyisocyanate. Big words!

Polyaspartic coatings were developed in the 1990s by the Germany chemistry giant Bayer as part of their research efforts to improve polyurea technology. Their goal was to create a coating that combined the fast-curing benefits of polyurea with better workability and pot life—essentially giving application specialists like Motorcity Floors and Coatings more time to work with the material before it hardens. The technology was initially patented and used in European markets before gaining traction in the U.S. in the early 2000s.

The polyaspartic material has chemical properties and qualities that make it much more suitable for patio coating than epoxy. Make no mistake: epoxy is a great material. It looks fantastic when applied correctly in the right situation. But it is not an outdoor material. It will degrade too fast to be a good investment for households. On the contrary, polyaspartic is the best existing coating material when associated as a topcoat to a polyurea base coat.

Based on our experience and customer feedback, we can list at least 8 reasons why a polyaspartic patio coating is the smartest choice to freshen up your outdoor space.

1. Durability

Polyaspartic patio coating is extremely durable when used with polyurea material correctly applied to the supporting surface. The molecules of the two materials bond strongly to make a coating that moves with the underlying surface. Concrete expands and contracts with temperature and humidity. The base coat (polyurea) and the topcoat (polyaspartic) stretch in sync with the motion of the concrete.

The bonds formed by other types of coatings, such as acrylics, are not as strong as this one. A polyaspartic patio coating will be able to withstand a lot of wear and tear without peeling or chipping and will keep looking great for years.

2. UV Resistance

UV resistance is another benefit of a polyaspartic patio coating. Epoxy, on the contrary, offers no UV resistance and takes on a yellow haze over time. Actually, epoxy will degrade faster when exposed to sunlight. We wrote a full article on the reasons why epoxy coatings fail.

3. Speed of Application

Unlike traditional urethane coatings, which are difficult to apply evenly, a polyaspartic coating can be applied quickly and easily to create a smooth, even finish. The polyaspartic material can be sprayed on in a matter of minutes and is ready to use almost immediately. This makes the application process faster than other types of coatings.

4. Short Drying Time

Polyaspartic patio coatings have a very short drying time: the polyaspartic material cures quickly when exposed to air. The upside? Homeowners don’t have to wait very long for their patio to be able to walk on their patio after the coating has been applied. The downside? The material does not lend itself to DIY application: professional applicators like MotorCity Floors and Coatings know how to handle it, and to prep up the work so that the spraying and the rest of the process happen within the short timeframe specified by the manufacturer.

5. Slip Resistance

Polyaspartic coatings don’t inherently offer slip resistance on their own—in fact, when applied as a clear, smooth finish, they cure to a glossy surface that can actually be quite slippery, especially when wet. The slip resistance associated with polyaspartic patio coatings comes from additives and application techniques specifically designed to create texture and traction.

The most common method consists in broadcasting aggregates—such as silica sand, aluminum oxide particles, or polymer grit—into the wet coating. These materials become embedded in the surface as the coating cures, creating a textured profile that provides grip underfoot. Additionally, polyaspartic patio coatings can be formulated with specialized non-slip additives mixed directly into the resin. This creates a slightly textured surface without requiring broadcast materials.

6. Ease of Maintenance

Do you prefer (like most of us) a low-maintenance coating? Polyaspartic coatings are a good choice for this purpose because of their dense, non-porous surface characteristics and exceptional chemical resistance. When properly applied, polyaspartic coatings cure to form a seamless, impermeable barrier that prevents liquids, oils, chemicals, and contaminants from penetrating into the substrate below.

This non-porous nature means that spills and stains sit on the surface rather than soaking in. This makes it simple to wipe them up with basic cleaning methods (a bucket and a mop, a hose and a brush). The resistance properties of the coating to a wide range of chemicals (e.g., household cleaners, automotive fluids, acids, and solvents) mean you can use stronger cleaning agents when necessary without worrying about damaging or degrading the finish. Regular maintenance typically requires nothing more than sweeping, dust mopping, or occasional damp mopping with mild detergents.

7. Environmental Awareness

Modern coating manufacturers like Covestro (formerly Bayer MaterialScience, the inventor of the polyaspartic material) have increasingly focused on sustainability initiatives in recent years. The European Union has explicit targets and regulations to reduce VOCs (volatile organic compounds). Like other chemistry giants, Germany-based Bayer is developing bio-based raw materials and incorporate circular economy principles into their supply chain.

8. Affordability Over Time

Polyaspartic coatings are generally not very affordable when looking strictly at upfront material and installation costs. In fact, they are typically one of the more expensive coating options available on the market. They usually cost significantly more per square foot than traditional epoxy coatings and even more than standard polyurethane systems.

Their higher initial cost reflects their advanced chemistry, faster cure times, superior performance characteristics, and the specialized application expertise required. For budget-conscious projects with short-term financial constraints, the initial price tag can be a significant barrier, making epoxy or other alternatives more attractive from a pure acquisition cost standpoint.

However, affordability must be evaluated through the lens of total cost of ownership over time. This is where polyaspartic coatings prove their value. Their exceptional durability, UV stability, chemical resistance, and abrasion resistance mean they typically last much longer than cheaper alternatives: often 15-20+ years compared to 5-10 years for standard epoxy systems.

This extended lifespan means fewer recoating cycles, which saves on both materials and labor costs over the decades. Additionally, low maintenance requirements reduce ongoing cleaning and upkeep expenses. In a commercial or industrial context, fast curing times minimizes costly downtime, offsetting a big part of the cost difference with typical epoxy systems.

Polyaspartic coatings become the more economical choice over their lifecycle, particularly in high-traffic or demanding environments (think Michigan) where harsh weather tests the durability of the coating every day.

Can You Trust MotorCity Floors and Coatings to Install Your Polyaspartic Patio Coating?

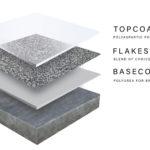

Today, we recommend our clients to opt for a blend of polyurea and polyaspartic patio coatings. We have perfected this type of dual coating to a high level of durability. Using a polyurea coat as the basecoat over the concrete surface, and the polyaspartic product for the topcoat, we are able to install in our clients’ patios and garages a coated flooring that flexes with the concrete, is extremely durable and easy to maintain, and will keep its beautiful appearance for years to come.

Call us at (248) 613-5888 to discuss your options. Our patio coating specialists have years of experience under their belt. They can ask you the questions that matter to make the correct decision and avoid a coating failure 3-5 years down the road.

MotorCity Floors and Coatings is a concrete coating specialist operating in Novi, MI. We serve clients across the entire Metro Detroit area. Our clients love our work, and they have given us a 4.9 rating in Google Reviews. We also have an A+ rating at the BBB.