What’s Not to Like About Residential Concrete Floor Coatings?

Residential concrete floor coatings protect floors from wear-and-tear and improve their appearance. They also make is easier to clean. What’s not to like about them? However, there are various types of coatings, and you have to know which one will fit your circumstances best. Your choice of coating material will depend on the intended use of the room.

Motorcity Floors and Coatings has been in the business of residential concrete floor coatings for many years. We have seen a lot of applications, good and bad, and tried a lot of materials: latex, epoxy, polyureas, polyaspartics, acrylics… In the end, our advice is to select the correct coating material for the job, the situation of the space to coat, and the volume of traffic that will enter and exit this space.

We’ll discuss the 4 types of materials used in most homes today.

1. Epoxy

Epoxy is a two-part resin that you mix with a hardener. The chemicals bind together and produce a rigid “plastic” layer. Epoxy has gained fame on YouTube for its artistic applications on wood tables. Itsprimary application though is for indoor concrete floors because of its properties: durable, resistant to wear-and-tear, binds nicely to most base layers.

Epoxy coatings find a use in protecting concrete floors from chemical spills (grease, bleach, oils, other harsh chemicals) and stains. These properties make epoxy a good choice for heavy-duty applications.

However, epoxy coatings can be challenging to apply. They typically require an experienced flooring contractor.

Apart from homes, epoxy coatings are a good choice for industrial facilities, warehouses, logistic centers, and places where heavy equipment is used.

2. Polyurethane

Polyurethanes are polymers thermosetting by nature. They are softer and more elastic than epoxy—perfect for moderate-to-heavy pedestrian traffic. They are also more resistant to abrasion, as the material absorbs the impact rather than only resisting it, which means fewer scratches to the surface.

Polyurethane coatings are well-suite to spaces like parking lots, freezing chambers, and commercial facilities (car dealerships, for instance). The appearance of a polyurethane coating flatters a showroom, with various degrees of sheen.

Polyurethane coatings do have some shortcomings though. They are sensitive to moisture and can quickly show bubbles and blemishes under unfavorable circumstances. Laying down a coat of polyurethane in an area affected by high humidity is a terrible idea.

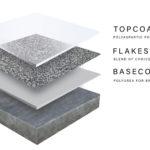

Motorcity Floors and Coatings has developed a proven polyurea-based process for residential concrete floor coatings. We use the polyurethane material as the base coat.

3. Polyaspartic

Polyaspartic coating results from combining resin with a catalyst, a process which facilitates the curing and hardening process. Initially, this coating material wasn’t doing well technically. It had to mature. With technological improvement though, polyaspartic coatings have become viable alternatives to epoxy and polyurethane.

Perhaps the best feature of the material is its customizability to anything. Professionals can manipulate polyaspartic coatings to control drying times and pot life. They are also easy to apply — taking half the time epoxy and polyurethane materials take — and reduce labor and material costs.

Polyaspartic coatings are well-suited to areas with medium-to-heavy foot traffic: airports, malls, shopping centers, and hospitals. However, this type of coating requires a more thorough surface preparation than the other materials. Motorcity Floors and Coatings uses polyaspartic material as topcoat in residential concrete floor coatings: garage, basement, walkway, patios, pool decks…

4. Acrylic

Acrylic is among the most common types of industrial coatings. This is a water-based material that is easy to apply and can be used in many different environments. Acrylics are also non-toxic, allowing contractors to apply them in food-handling facilities.

Acrylics can be used to coat surfaces exposed to sunlight, humidity, and high temperatures. Often used in areas with medium-to-heavy foot traffic (e.g., offices, schools), it is also used in areas which see little-to-no traffic such as a basement. It comes in various colors.

The material has some downsides, though. It is less durable than epoxy or polyurethane.

Residential Concrete Floor Coatings: Our Recommendation

Over the years, we have developed and refined a concrete floor coating application for homes in Novi, MI and in the Metro Detroit area. Our approach blends the benefits of polyurethane and polyaspartics. We start by preparing the concrete floor. Then grind it to open its pores and ensure maximum adherence of the base coat.

After which, we fill out and repair any section pitted and cracked. This ensures that the coats will be absolutely even when we lay them down. We then apply a base coat of polyurea. One of the benefits of using polyurea as a base coat is to act as a vapor barrier for the humidity coming from under the concrete. It stops the humidity completely, and prevent it from touching the topcoat. The base coat also penetrates the pores of the concrete to a very high level of adherence.

After the polyurea base coat has cured, we apply a coat of polyaspartic material. This coat will prevent chemical spills from reaching the concrete and staining it. It will also act as a barrier to humidity, while creating a very smooth surface easy to clean and beautiful to look at. This dual system dries quickly, and your basement, garage, walkway, patio, pool deck is ready to be used the next day or before. We typically take only 1 day to install a residential concrete floor coating.

MotorCity Floors and Coatings is a concrete floor coating company based in Novi, MI and serving the entire Metro Detroit area. We offer floor coating services to residential, commercial, and industrial customers. If you are considering coating your concrete floor, give us a call at (248) 613-5888 to discuss with a specialist and receive the advice you need. With a 4.9 rating in Google Reviews, our customers have expressed that we are a safe, reliable flooring contractor.