This is a legitimate question: why would a polyurea coating outperform an epoxy coating, and in which circumstances?

If you plan to protect your concrete floor—whether it’s in your home garage, in a commercial warehouse, the floor of an outdoor patio, or a factory floor—the coating you choose makes all the difference. MotorCity Floors and Coatings has installed thousands of floor systems across in Michigan. We have seen firsthand how the right coating system will last 15-20 years, while the wrong one will fail in just 3-5 years.

Most homeowners and business owners have heard of epoxy floor coatings. But they don’t have the same level of information about polyurea coating technology. In this article, we’ll explain exactly what polyurea is, why our dual-layer polyurea coating system outperforms traditional epoxy, and how to determine if this is the right choice for your specific needs.

Polyurea Coating: What is It?

Polyurea is an advanced elastomer coating created through a chemical reaction between an isocyanate component and a resin blend. Unlike epoxy, which hardens through a curing process, polyurea forms molecular bonds that create an extremely strong, flexible membrane on your concrete surface.

Think of it this way: epoxy is like a hard shell that can crack under stress. Polyurea is like a flexible armor that moves with your concrete, absorbing impacts and temperature fluctuations without breaking down.

The MotorCity Dual-Layer System

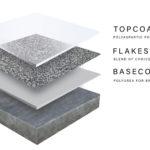

At MotorCity, we don’t just apply a single polyurea coating and call it done. We use a proven dual-layer system that maximizes both performance and longevity:

- Aromatic Polyurea Base Coat: This foundation layer penetrates deep into the concrete (which we carefully prepared), creating maximum adhesion and acting as a moisture vapor barrier. It is the structural backbone of the system.

- Polyaspartic Topcoat: This specialized polyurea layer provides exceptional UV resistance (preventing yellowing), superior chemical resistance, and creates the glossy, showroom finish. It also adds extra hardness to resist abrasion.

This combination gives you the best of both worlds: structural integrity from the base layer and weather protection from the topcoat. It is specifically engineered for the harsh climate of Michigan—going from subzero winters to hot, humid summers.

Understanding Different Polyurea Systems

Not all polyurea coatings are created equal. Here’s what you need to know:

- Pure Aromatic Polyurea: Offers the strongest adhesion and moisture resistance. Ideal for base coats but can yellow when exposed to UV light, making it unsuitable for outdoor topcoats.

- Aliphatic Polyurea (Polyaspartic): Provides excellent UV stability and won’t yellow over time. Perfect for topcoats, especially on outdoor surfaces like patios and pool decks.

- Hybrid Systems: Combine the strengths of different polyurea types, like our dual-layer system, to optimize performance for specific applications.

Important: Epoxy is NOT a type of polyurea. These are completely different chemical systems. Epoxy is a thermosetting resin, while polyurea is an elastomer. They have entirely different properties, strengths, and weaknesses.

Polyurea Coating vs. Epoxy Coating: A Comparison

In the table below we created an objective comparison based on real-world performance data from our installations in Michigan:

| Feature | Polyurea | Epoxy |

| Cure Time | 24 hours (drive on next day) | 3-7 days |

| UV Resistance | Excellent (won’t yellow) | Poor (yellows and chalks) |

| Flexibility | High (moves with concrete) | Rigid (cracks with movement) |

| Hot Tire Pickup | None | Common problem (tire marks) |

| Temperature Range | -40°F to 300°F | -10°F to 140°F |

| Tensile Strength | 4,000+ PSI | 1,200-1,500 PSI |

| Expected Lifespan | 15-20+ years | 5-10 years |

| Initial Cost | Higher (30-40% more) | Lower |

| Cost Per Year | Lower (40% savings over time) | Higher (needs replacement sooner) |

Real-World Performance: What Our Customers Experience

Michigan’s Freeze-Thaw Challenge

In Michigan, we experience extreme temperature swings—from -10°F winter nights to 95°F summer days. This freeze-thaw cycling is brutal on concrete and coatings. The rigidity of epoxy causes it to crack as the concrete beneath expands and contracts. We have seen epoxy coatings in unheated garages fail within 3 years!

The flexibility of a polyurea coating allows it to move with the concrete, preventing the micro-cracks that lead to delamination. One of our customers in Rochester Hills has had his polyurea garage floor for 12 years through 12 Michigan winters, and it still looks “showroom-new”.

The Hot Tire Problem

If you’ve ever driven home on a hot summer day and parked on an epoxy floor, you may have noticed your tires stick slightly when you back out the next morning. This is called hot tire pickup—the heat from your tires softens the epoxy, causing it to literally peel off with your tires.

The higher heat resistance of a polyurea coating (up to 300°F) means hot tire pickup simply doesn’t occur. Your floor stays intact no matter how hot your tires get.

Case Study: Commercial Warehouse Installation

We installed a polyurea system in a very large warehouse in Michigan some years ago. This floor sees daily forklift traffic, chemical spills from automotive fluids, and temperature extremes. Years later, the floor shows minimal wear—some surface scratches in the highest-traffic lanes. Our client estimates our system has saved them over $50,000 in replacement costs compared to their previous epoxy floor, which needed refinishing every 4-5 years.

Benefits of Polyurea Coatings

Speed and Convenience

- One-day Installation: Most residential garage floors can be completed in one day, and you can park on it the next day. Compare that to the 5-7 day process required by epoxy where your garage is unusable.

- Year-Round Application: A polyurea coating can be installed in temperatures as low as 20°F. This means we can work through Michigan winters. By comparison, epoxy requires temperatures above 50°F.

Durability and Longevity

- Abrasion Resistance: High tensile strength of a polyurea coating (4,000+ PSI vs. 1,200-1,500 PSI for epoxy) means it resists scratches, scuffs, and impact damage far better than epoxy.

- Chemical Resistance: Resistant to automotive fluids, de-icing salts, household chemicals, and even battery acid. Spills wipe up easily without staining or etching.

- Moisture Vapor Barrier: Our aromatic polyurea base coat creates an impermeable barrier, preventing moisture from wicking up through your concrete. This is critical in Michigan basements and garages.

Aesthetic Appeal

- UV Stability: Your floor won’t yellow or fade, even with direct sunlight exposure. Perfect for outdoor patios and garages with windows.

- High Gloss Finish: The polyaspartic topcoat creates a showroom-quality shine that stays glossy for years, not months.

- Customizable: Available in dozens of color combinations with decorative flake options to match any aesthetic.

An Investment: Why Polyurea Costs More (and Why It’s Worth It)

Let’s address the elephant in the room: A polyurea coating typically cost 30-40% more than an epoxy coating initially. For a standard two-car garage (400 square feet), you might pay $2,000-$2,800 for polyurea versus $1,500-$2,000 for epoxy.

But here’s the financial reality:

- Epoxy lifespan: 5-7 years average in Michigan conditions

- Polyurea lifespan: 15-20 years average

Over a 20-year period:

- Epoxy cost: $6,000-$8,000 (3-4 replacements at $2,000 each)

- Polyurea cost: $2,500-$3,000 (one installation)

That’s a savings of $3,000-$5,000, plus you avoid the hassle and disruption of multiple re-installations.

Additionally, a polyurea coating installation takes just 1 day with a 24-hour cure, while epoxy takes 2-3 days to install with a 5-7 day cure. The reduced disruption alone has value—especially for businesses that would lose productivity and revenue during a longer installation.

Polyurea Coating Requires Professional Installers

Unlike DIY epoxy kits available at home improvement stores, a polyurea coating requires professional equipment and expertise. This isn’t a drawback—it’s an advantage. Here’s why:

- Proper Surface Preparation: We use diamond grinding equipment to properly profile your concrete, ensuring maximum adhesion. DIY chemical etching rarely achieves the same results.

- Controlled Application: Polyurea coating must be applied with specialized plural-component spray equipment that precisely mixes and heats the material. This ensures consistent thickness and proper chemical bonding.

- Moisture Testing: We test your concrete for moisture content and pH levels before installation. Applying any coating over wet or alkaline concrete guarantees failure.

- Crack and Joint Preparation: We properly fill cracks and address control joints to prevent future issues.

At MotorCity, we back our installations with a residential warranty because we know our process works. Professional installation isn’t an added expense—it’s an investment that ensures your floor performs as promised.

When to Choose Polyurea: Decision Framework

Polyurea is the optimal choice for:

- Residential garages where you want a showroom finish that lasts decades

- Outdoor patios and pool decks that need UV resistance

- Commercial warehouses with heavy equipment traffic

- Automotive facilities where chemical spills are common

- Food service areas needing antimicrobial surfaces

- Basements requiring moisture vapor barriers

- Any high-traffic area where long-term durability justifies higher initial investment

Consider other options if:

- You’re in a temporary space and won’t benefit from the 15-20 year lifespan

- The budget absolutely cannot accommodate professional installation (though we have financing options)

- The surface is in such poor condition that extensive concrete repair would be needed first (though we can assess and provide options)

How We Prepare Your Surface for Polyurea Application

Proper surface preparation is 80% of a successful floor coating installation. Here’s our proven process:

Step 1: Surface Cleaning and Inspection

We begin by thoroughly cleaning your concrete to remove all dirt, oil, grease, and existing coatings. After inspecting for cracks, spalling, and moisture issues, we use specialized equipment to test moisture levels (must be below 4%) and pH (must be 6-9).

Step 2: Diamond Grinding

Unlike acid etching or simple cleaning, we use professional diamond grinding equipment to mechanically profile your concrete. This creates the ideal surface texture (CSP-2 to CSP-3) for maximum coating adhesion. Diamond grinding also removes surface laitance and opens the concrete pores.

Step 3: Crack and Joint Repair

We fill all cracks with flexible polyurea crack filler and address control joints with appropriate materials. This prevents future cracking from telegraphing through your new coating.

Step 4: Final Cleaning

We vacuum and damp-mop the prepared surface to remove all grinding dust. The floor must be completely clean and dry before coating application.

Step 5: Application

We apply the aromatic polyurea base coat using specialized plural-component equipment, broadcasting decorative flakes if desired. Once set, we apply the polyaspartic topcoat for UV protection and additional durability. The entire process typically completes in 6-8 hours, with a 24-hour cure before use.

The Bottom Line

MotorCity Floors and Coatings has been installing floor coating systems across Michigan for years. We’ve seen every type of floor coating succeed and fail. Based on 15 years of real-world experience, we can say with confidence that a polyurea coating consistently outperforms an epoxy coating in durability, longevity, and total cost of ownership—especially in the challenging climate of Michigan.

True, a polyurea coating for your garage will cost more upfront. But when you factor in its 15-20 year lifespan, resistance to hot tire pickup, UV stability, flexibility in extreme temperatures, and rapid installation time, it is the clear winner for anyone serious about protecting their concrete investment.

Our dual-layer system—combining an aromatic polyurea base with a polyaspartic topcoat—gives you the best of both worlds: structural integrity and weather protection. It’s why we back our residential installations with a lifetime warranty.

If you are considering a floor coating for your garage, basement, patio, or commercial space, we invite you to see the difference for yourself. Contact MotorCity Floors and Coatings at (248) 613-5888 for a free assessment and quote. Let us show you why a polyurea coating isn’t just any coating—it’s a long-term investment in your property.