Polyurea concrete floor coatings are sought after for the speed of the installation and hardening process. They also last a long time due to the chemical bond formed with concrete. However, the two-ingredient combination required by polyurea coatings results in a lot of quality variations between products. This impacts the performance of the coating: some types are less durable than others.

Polyurea is a two-part compound that combines a basic chemical ingredient, an isocyanate, with a resin blend. Isocyanate is what determines the chemical reaction that is unique to polyurea. At the same time, the resin blend can be a variety of property enhancers determined by the intended use.

There are many polyurea products on the market. Users must be aware of their differences and benefits before selecting a contractor to coat a concrete surface.

Polyaspartics: Affordable Applications

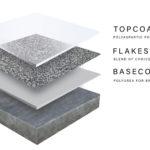

A polyaspartic is a polyurea that cures more slowly than usual. This allows the coating to be applied over a longer period, more traditionally. Polyaspartic mixtures work well as a topcoat in a concrete floor coating application. However, they have limitations when used as a base coat.

Before we continue, remember: all polyaspartics are polyurea. But not all polyurea are polyaspartic.

A polyaspartic basecoat is cheaper than a pure aromatic polyurea. But its strength and durability are not the same. When you use a polyaspartic basecoat, you incur a great risk of cracking and delamination.

Aromatic Polyurea: Reliable Base Coat Applications

Aromatic isocyanates are not light-stable. The color of the coating fades when exposed to sunlight. However, the coating will not deteriorate as would a polyurea polyaspartic coating. Because of this light sensitivity, aromatic polyurea is not the best choice as a topcoat. But it can be used as a strong and reliable base for concrete flooring coatings.

To apply an aromatic polyurea base coat and obtain the best durability, precision is key. For optimum adhesion, professional installers use seasonal blends to adjust the curing time according to the ambient temperature. Base coats are a 1:2 ratio of A–B. Choosing a blend determines the maximum time available to apply the base coat after mixing. You need to use the correct mixture and the correct timing to avoid mistakes resulting in peeling and cracking.

Aliphatic Polyurea: Reliable Top Coat Applications

This type of polyurea comprises long-chain molecules that do not contain any aromatic groups. This makes them non-polar and gives them good resistance to water and other chemicals. They are also very tough and elastic. That property makes them well-suited to numerous industrial and commercial applications.

Additionally, aliphatic systems are light-stable. They don’t change color when exposed to light. This explains why they are popular as a topcoat. They also have a high-gloss finish that adds value to the looks of your space.

To mix aliphatic polyurea, professionals use a variable-speed cordless drill at a low speed. This is to avoid air bubbles in the mixture. The ratio for mixing is 1:1 of A-B. There are different blends based on the curing time. If you want to ensure an extended life, use an extreme-heat mixture. Apply the topcoat once the base coat has hardened. You must also scrape and clean the base coat before applying the topcoat.

Reference materials:

Polyurea, polyurea base coat: www.corrosionpedia.com/

One-Day Concrete Floor Coatings by MotorCity Floors and Coatings

As noted earlier, one of the advantages of polyurea coatings is that they can be applied quickly. And that’s not all: they also have a long lifespan, and they resist abrasion and chemicals. These properties ultimately depend on their mixture and purity. This must be clarified these with your supplier or your contractor before making the final call.

Call MotorCity Floors and Coatings at (248) 613-5888 to discuss your project. We install premium concrete floor coatings for residential, commercial, and industrial clients. Our concrete floor coatings are 4 times stronger than epoxy. Get a quote today.